ELIPSYS® & Direct Laser Interference Patterning (DLIP)

The patented ELIPSYS® platform enables the fastest, most precise utilization of the direct laser interference patterning (DLIP) technology, so you obtain periodic, functional surface structures in record time.

Direct Laser Interference Patterning - DLIP

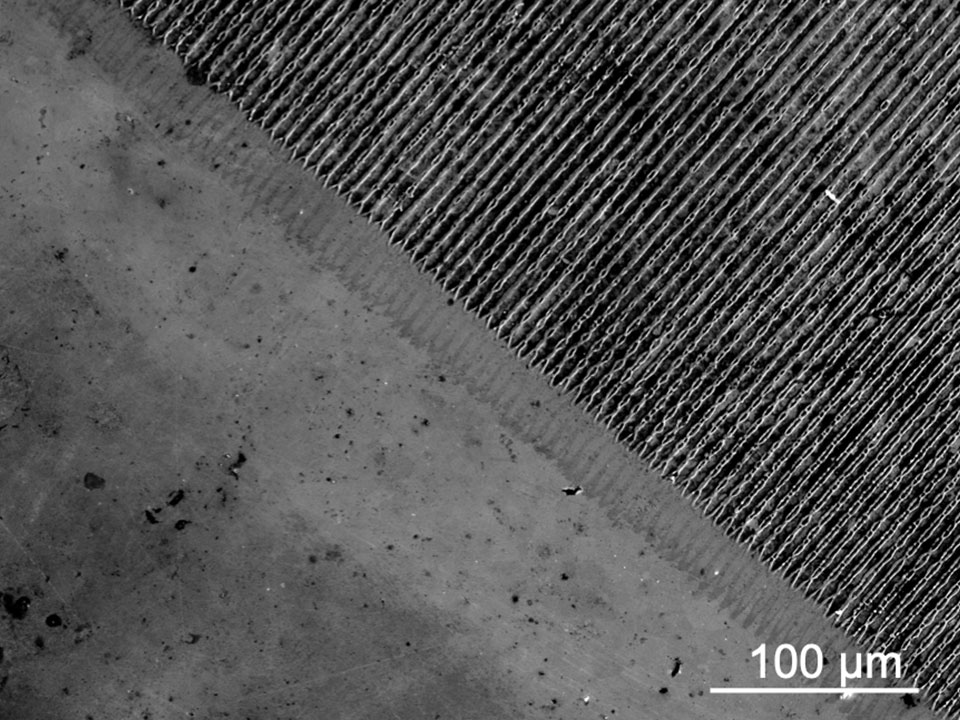

For deterministic structural geometries smaller than 20 µm (by comparison: a human hair has a diameter of approx. 60 µm), there is hardly any technology that can produce these structures at industrially relevant process speeds.

However, when surfaces of living nature are analysed, it is found that almost all highly effective, functional surface structures (e.g. the water-repellent lotus effect of the lotus plant or physical color effects on the wings of a butterfly) are in this order of magnitude of less than 20 µm.

Extended Laser Interference Patterning System - ELIPSYS®

ELIPSYS® is the latest generation of DLIP technology, enables the extremely fast and cost-effective generation of complex surface structures that improve the properties of a wide range of products (e.g. non-stick, antibacterial, energy-efficient, low-friction, electrically highly conductive or forgery-proof). DLIP and ELIPSYS® mark a turning point in the production and functionalization of material surfaces for a wide range of industries.

Direct Laser Interference Patterning (DLIP) is a technology from the field of laser structuring that exploits the physical principle of interference and thus reliably masters precisely the technological challenge described above at industrially relevant process speeds.

Functionally highly effective, microscopically small structures (sub-µm to µm) can be generated in record speeds (m²/min) by splitting and superimposing at least two laser beams on the material surface to be processed.

Test DLIP feasibility

Find out now how you can use this groundbreaking technology to your advantage and test the feasibility directly on your products!

We accompany you throughout the entire process of technology transfer, from the test of feasibility on your product, to the production of compact optical solutions (DLIP optics) for automated, fast handling of your products („DLIP Pre Series“), to serial production equipment or DLIP systems for your production line or in-house at SurFunction („DLIP Enhancement“) – all by one supplier, SurFunction!

How DLIP works

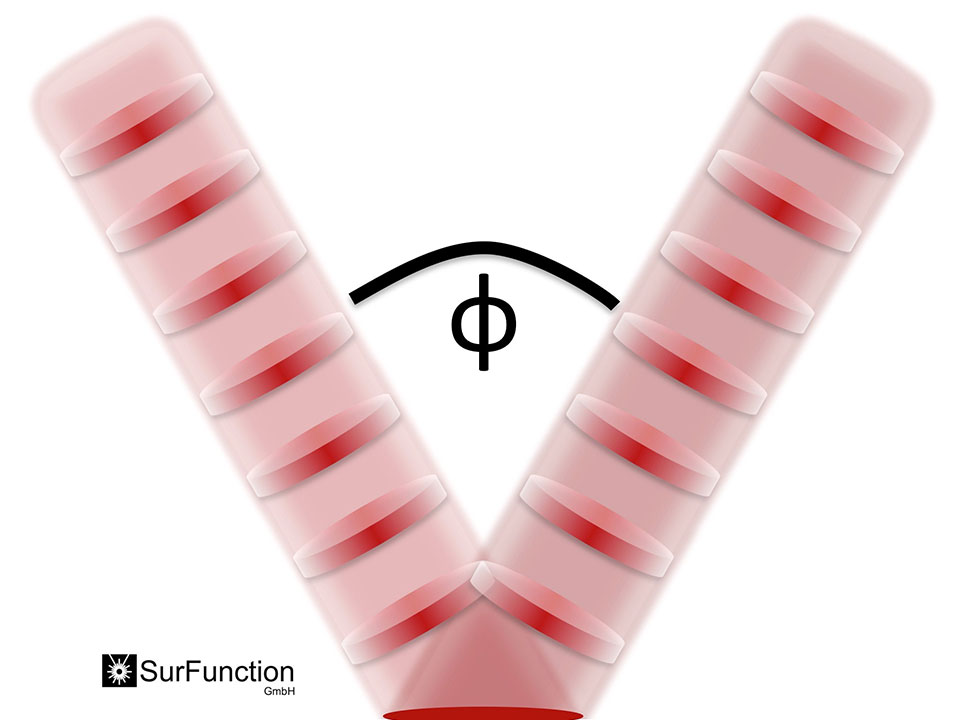

The phenomenon of laser interference is based on the interaction of at least two superimposed laser beams (electromagnetic waves) and is about similar to the interaction of water waves.

If a wave peak of the first wave meets a wave peak of the superimposed, second wave, this results in the formation of a larger wave peak, called constructive interference. If a wave valley hits a wave peak, the wave is extinguished, called destructive interference.

In a similar way, electromagnetic waves (laser beams) are used to generate intensity patterns, which are projected onto the surface of the component. The material is melted or even vaporized in areas of constructive interference, while it remains almost unaffected in areas of destructive interference.

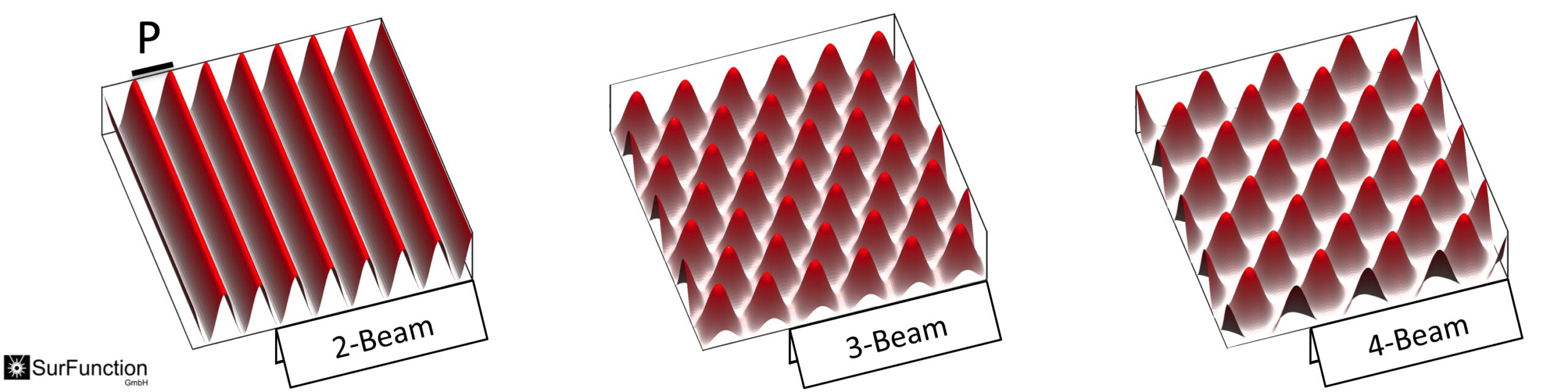

The number and arrangement of the beams in relation to each other is decisive for the type of pattern applied. This can be, for example, a line, cross, dot pattern or almost any periodic surface pattern.

The angle φ between the superimposed laser beams and the wavelength λ of the used laser decide in turn on the structure size (period P) of the applied periodic intensity pattern (exemplary intensity pattern for symmetrical arrangement of 2, 3 and 4 beams shown).

Depending on the material to be processed (polymer, metal, ceramic, glass), the appropriate laser can be selected, since the wavelength of the laser, typically in the range from UV to NIR, determines the degree of reflection or absorption on the material surface.

Due to the use of laser radiation, the possibilities of influencing the surface functionality go far beyond a mere topographical modification. The laser-induced energy coupling by means of DLIP technology allows for a highly localized, periodic manipulation of the material properties.

The direct laser interference structuring can thus be individually and flexibly adapted to the materials, surfaces and also geometries of your components or products to be processed and can optimize them in an almost unlimited variety of variants. The possibilities of the technology seem almost unlimited!

Benefits of DLIP

Compared to other high-precision surface structuring methods, such as lithography or chemical etching, the advantages of direct laser interference patterning quickly become clear.

No additional coatings, masks or chemicals are required and with DLIP, a multi-stage process turns into a one-step process that is also contactless and therefore not only more sustainable but also faster.

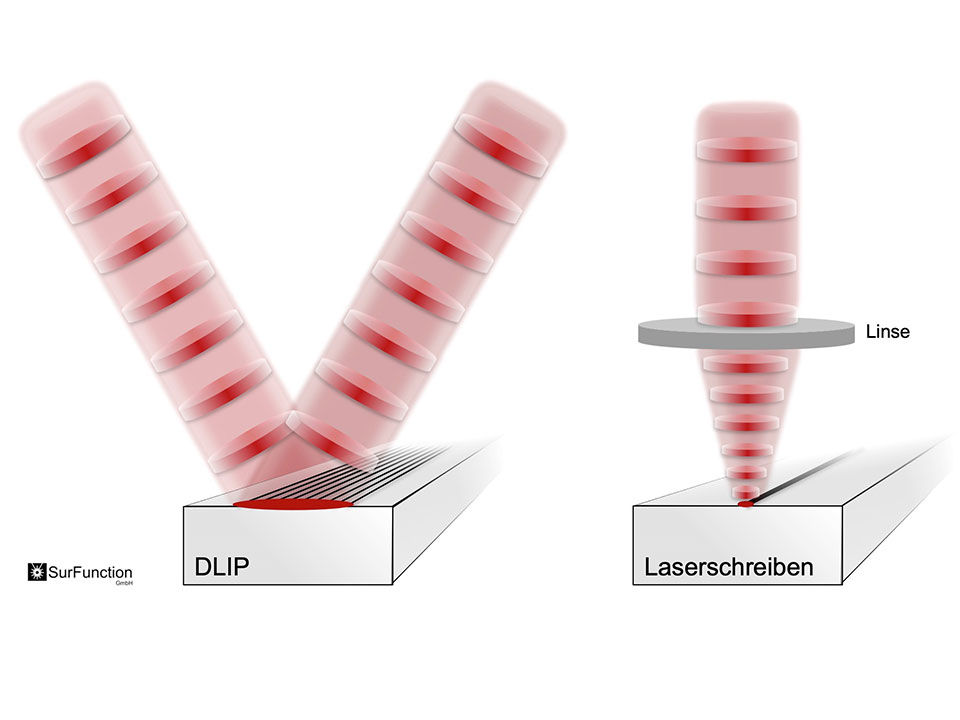

The advantage of the process over other, conventional laser processes is that the surface pattern to be applied is stored as an interference pattern throughout the entire laser beam diameter and hundreds to thousands of structures in micro or nano dimensions are applied to the surface in a few nano- to femtoseconds with just one laser pulse.

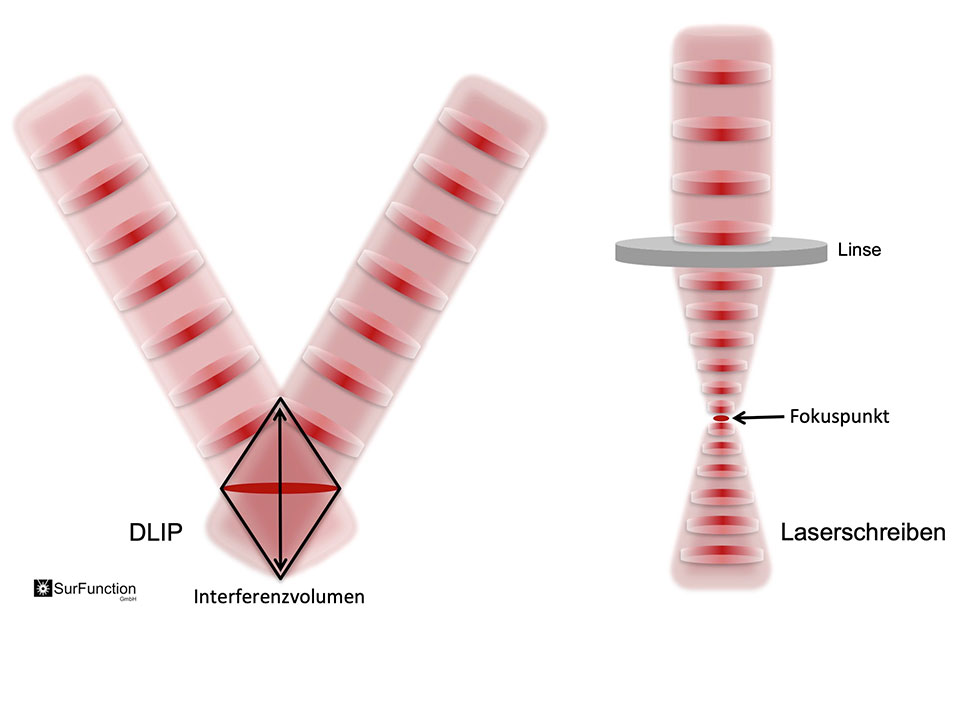

In contrast to other, equally fast processing methods, such as laser writing using polygon scanners, the beam diameter does not have to be focused, but can even be expanded depending on the required pulse energy, in order to create microscopically small structures with a significantly larger processing area per laser pulse.

DLIP, combined with a modern high-frequency laser, thus achieves processing speeds in the range of m²/min with highest precision down to the nanometer range. The use of a polygon scanner is also possible with DLIP to achieve even faster process speeds.

In addition, the DLIP process has a very high depth of focus compared to laser writing, since DLIP does not depend on precise focusing of the laser beam, but creates a spatial “interference volume” within which the surface is equally structured with the corresponding interference pattern. DLIP is therefore not only more economical, but also less susceptible!

DLIP Applications

DLIP can already be used very successfully in several application fields. The current range of services covers the following application fields:

Enhanced Connectivity

Hygienic Surfaces

Optimized Friction and Wear

Improved Absorption

Improved Security

Tailored Wetting

Do you have any questions?

Contact us now. Our experts will be happy to help you!

Big changes start on a small scale.

Contact the SurFunction GmbH team of experts now. We will be glad to show you how you can start into the next generation of your products with DLIP!