Surface Treatment

In the field of surface processing, it has long been clear that the surface quality of a product, component, tool or machine is not only interesting from a decorative point of view.

Nowadays, the functionality of a product is largely determined by its surface properties. On the one hand, it is possible to apply coatings (e.g. hard metal coatings, organic lacquers, etc.) to a surface in order to optimize it for the intended purpose. On the other hand, it is also possible to process the existing surface in such a way that the product can fulfill its intended functions much more efficiently and with a longer service life.

Existing technologies for surface treatment

There are many technologies for surface treatment.

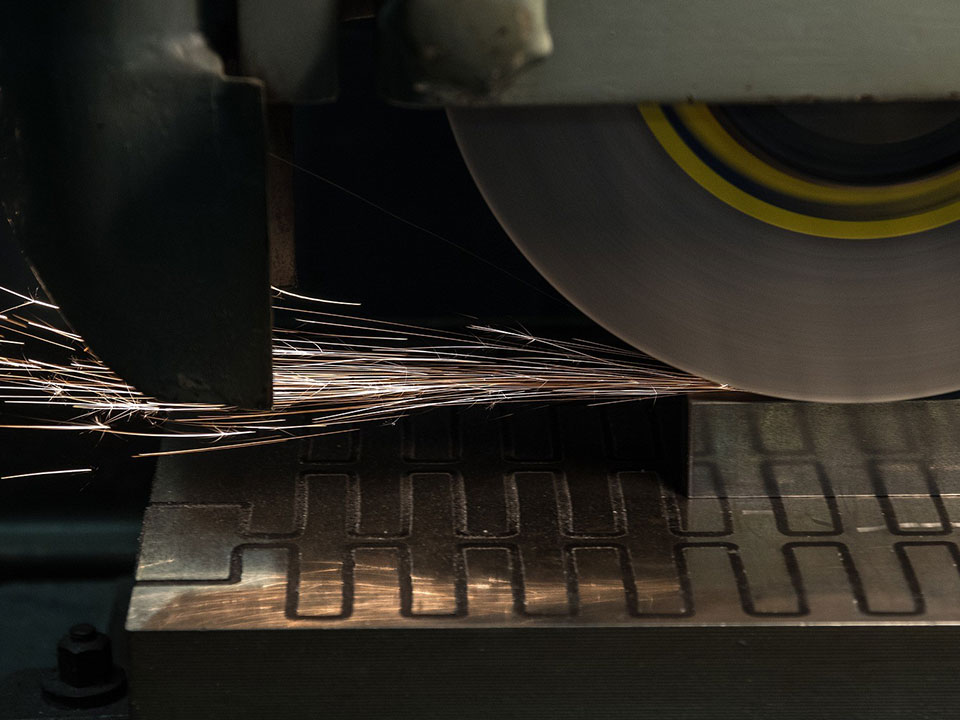

On the one hand, these include conventional mechanical processes such as grinding, polishing, lapping, brushing, honing, milling, etc., which all have in common that they change the surface roughness (smoothing or roughening).

The roughness measures obtained in this way can nowadays be described and measured by means of numerous standardized values.

Surfaces in nature

On the other hand, a look at living nature shows that all surfaces are geometrically structured in a wide range of size scales and have thus been perfectly adapted to their respective functionalities during evolution, such as

- the leaf of the lotus plant,

- the wings of a butterfly or

- the skin of a shark.

Nowadays, surface treatment processes in particular are of great technological relevance. They are able to produce the intended microscopically small patterns on a surface and thus produce a surface that is almost tailor-made for the respective application.

In this context we generally speak of surface structuring.

Surface structuring

A specific, microscopic surface structuring (apart from the often used statistical roughness measures for the description of technical surfaces) allows for a defined surface functionalization in almost every technological field of application based on nature’s example.

There are already numerous possibilities to provide surfaces with specific functional structures.

On the one hand, these possibilities lie in the area of classical, mechanical processes, such as micro milling or micro embossing.

What these processes have in common is the use of a mechanical tool to process the surfaces to be functionalized.

This is also to be seen as a limitation at the same time, since many surfaces can only be processed with difficulties using mechanical tools or the processing is connected with a frequent exchange of the tool due to tool wear.

In addition to these processes, methods such as chemical etching or lithographic methods are also used. These methods are often highly precise, but usually require several process steps, which strongly influences their process speed and thus makes them comparatively slow and thus less economical.

Due to these facts, more and more laser technologies are being used today for surface structuring, since record speeds are achieved with high precision at the same time – and this completely contact-free and thus almost “wear-free”.

Learn more about different processes, advantages and applications in the field of laser structuring or contact us directly.

Do you have any questions?

Contact us now. Our experts will be happy to help you!

Big changes start on a small scale.

Contact the SurFunction GmbH team of experts now. We will be glad to show you how you can start into the next generation of your products with DLIP!