According to the Society for Tribology (GfT), costs caused by friction and wear account for around 2-7% of the gross national product (GNP) of an industrial nation. Reducing friction and wear is therefore economically worthwhile and sustainable. Using DLIP technology, it is possible to specifically influence friction and wear on mechanically stressed surfaces.

Friction & wear reduction with DLIP

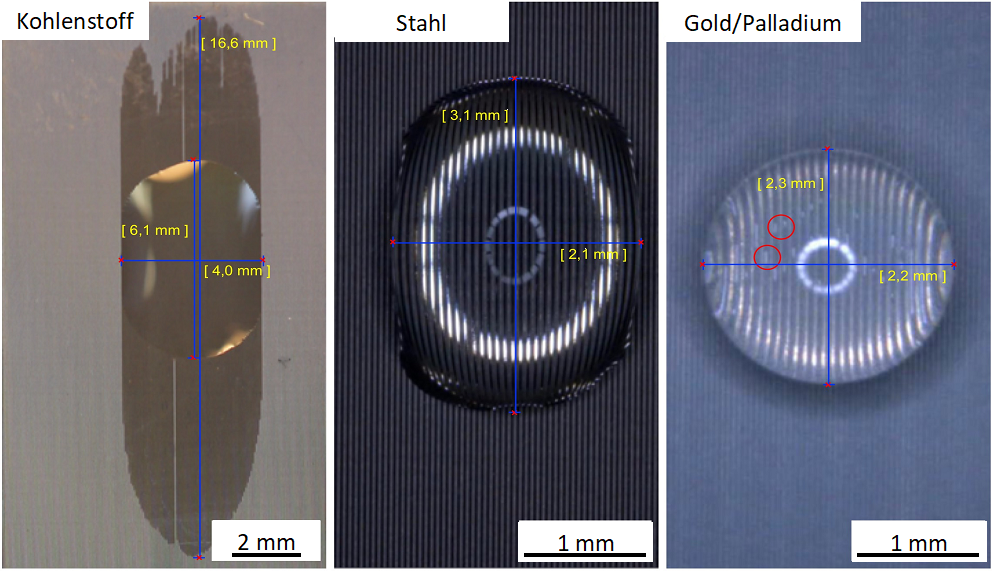

DLIP surface structuring can have a direct influence on the real, microscopic contact area of surfaces and thus specifically control friction and wear for a wide variety of mechanically stressed components and applications

The following is possible, among other functions

Directionally dependent wear

Setting different friction values depending on the direction of movement on a component surface.

Adjustment of lubricating film thicknesses

DLIP structures can build up additional hydrodynamic pressure and manipulate the lubricant film thickness, which is crucial for the separation of the friction partners involved.

Microscopic lubrication reservoirs

“Pockets” can be created in the surface as a reservoir for lubricants (e.g. oil or solid lubricants), which continuously supply the surface with lubricant and prevent insufficient lubrication. Generated wear particles are also stored in the pockets in order to minimize abrasive wear caused by third-party bodies.

Lubricant transport (tailored wetting)

DLIP allows the wetting properties of surfaces to be specifically influenced:

- Directionally dependent wetting: Channel-like surface structures can cause strong and direction-dependent wetting through capillary action.

- Reduction of surface wetting: Repellent surfaces can be created or the spread of a liquid in a certain direction can be reduced.

For example, undesirable lubricant migration (oil) out of the contact area of the tribological load and thus a lack of lubrication can be effectively avoided, thereby effectively increasing the average service life of a component.

Contact

Contact us - our experts will be happy to help you!

Do you want to learn more about tribology?

The team at SurFunction GmbH has years of experience in the field of tribological properties of DLIP treated surfaces.