DLIP – Direct Laser Interference Patterning on the ELIPSYS® Platform

By splitting and overlapping at least two laser beams on the material surface, DLIP generates highly functional microstructures (sub-micron to micron scale) at record speeds – measured in square meters per minute.

Our patented ELIPSYS® platform enables the fastest and most precise implementation of DLIP, delivering periodic, functional surface structures in record time. These structures significantly enhance product properties, such as anti-stick, antibacterial, energy-efficient, low-friction, highly conductive, or counterfeit-resistant surfaces.

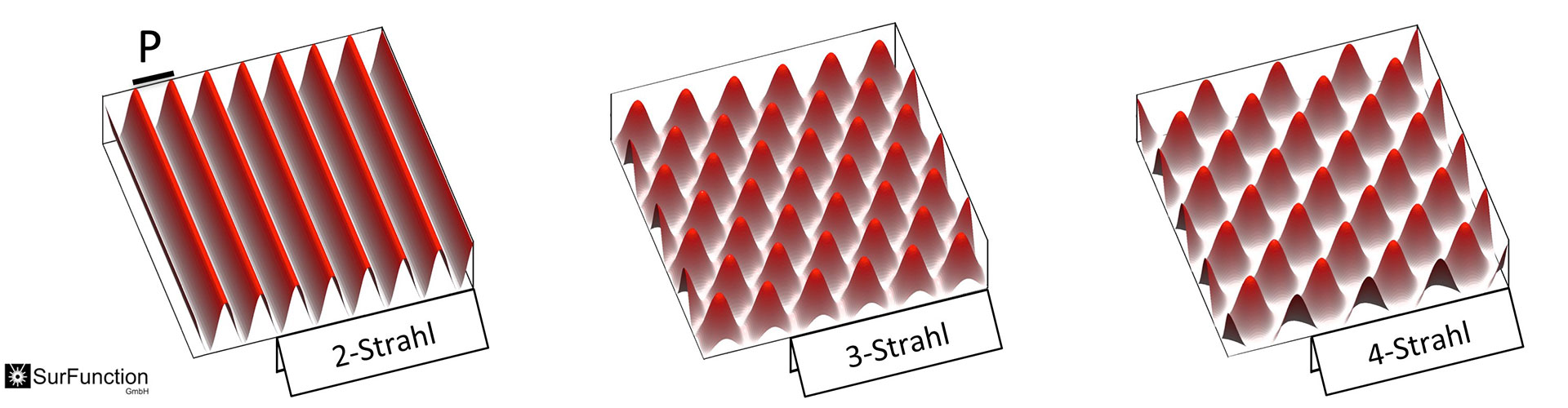

The laser interference phenomenon is based on the interaction of overlapping electromagnetic waves, creating intensity patterns that are projected onto the surface – without altering the material itself. The number and arrangement of beams determine the resulting pattern, which can be configured as lines, grids, dots, or virtually any periodic surface design.

Depending on the material – polymer, metal, ceramic, or glass – the appropriate laser wavelength (UV to NIR) is selected to optimize reflection or absorption. DLIP can be flexibly adapted to various materials, surfaces, and geometries, offering nearly limitless possibilities for surface optimization.

Key Advantages of DLIP

- Ultra-precise structuring on nearly any material

- High-speed processing with deep focus and uniform results

- Thousands of micro- or nanostructures applied in a single laser pulse

- Compatible with other surface technologies for enhanced functionality

Contact

Contact us! Our experts will be happy to assist you.