Services

Material Intelligence

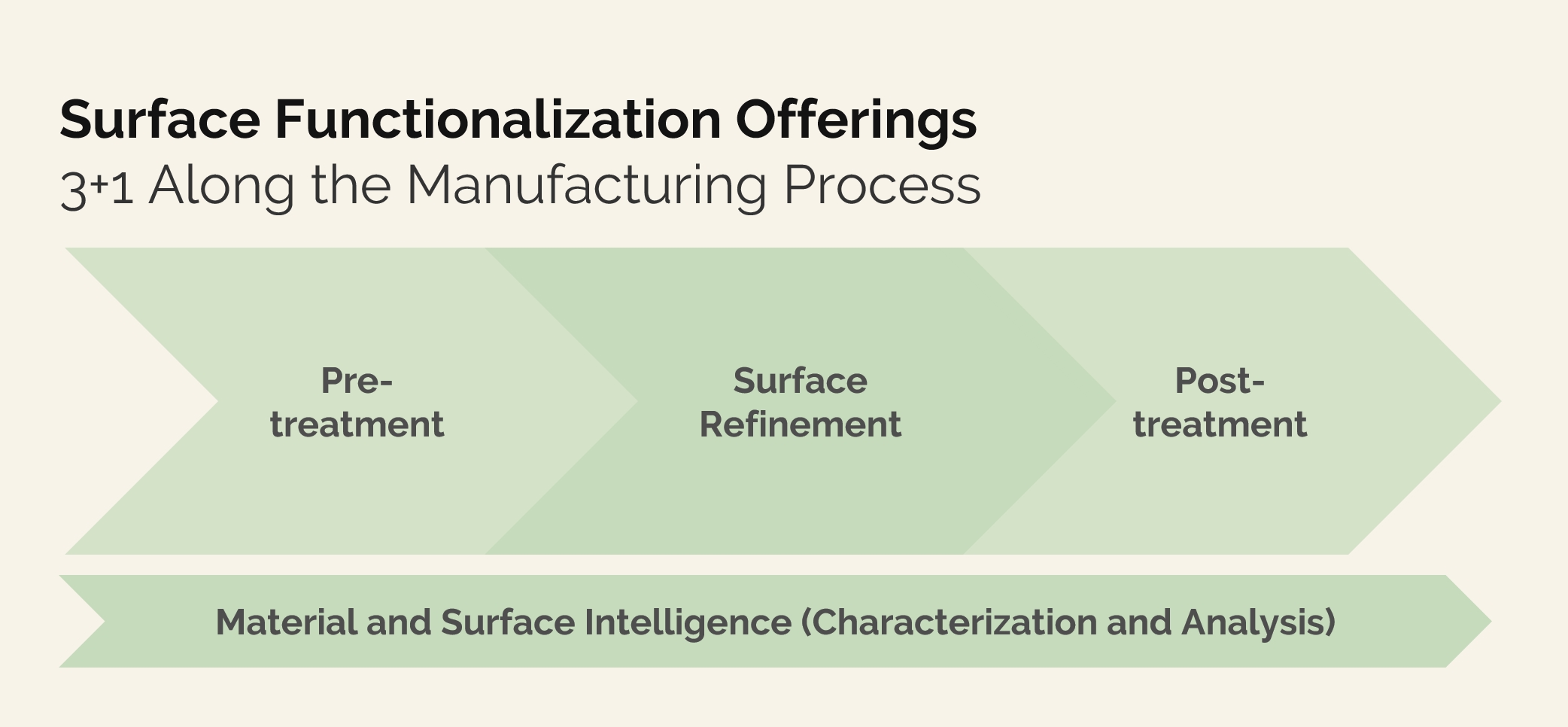

We begin with a precise material analysis to understand the properties of the substrates to be refined. This is essential for identifying the most effective surface enhancement solutions tailored to your specific needs.

Surface Preparation

We prepare surfaces using advanced mechanical and physical processes to ensure optimal results. These include:

- Homogeneous topographies and defined roughness profiles

- Stabilized edges and micro-geometries for cutting and forming tools

- Removal of unwanted residues such as co-leaching, oxides, or micro-burrs

- Improved coating adhesion and extended tool life

Our preparation methods include grinding, polishing, deburring, precision cleaning, and targeted edge rounding—customized to the material type and intended function.

Surface Functionalization

From our portfolio of complementary technologies – including DLIP, vacuum coatings, and wet chemistry – we select the ideal solution to give your materials the surface functionality they require:

- Friction Control

• Reduced friction

• Minimized wear

• Anti-stick properties

• Lower insertion force

- Absorption Enhancement

• Increased light absorption for energy generation

- Design Features

• Anti-counterfeiting protection

• Interference color effects

• Premium color finishes

- Wettability Control

• Superhydrophobic surfaces

• Superhydrophilic surfaces

- Antimicrobial Protection

• Antifungal

• Antiviral

• Antibacterial

Our technologies deliver measurable performance improvements while replacing labor-intensive manual processes with reproducible, automated, and cost-efficient solutions.

Post-Treatment & Finishing

We refine coated components to further optimize their functional properties and extend their durability in real-world applications. This includes:

- Surface structuring or smoothing

- Removal of process residues

- Laser fine-tuning for tribological or optical modifications

- Hydrophobic finishing or anti-reflective treatment

The result

Technically and visually perfect interfaces, precisely tailored to your application.

Our solutions are used across a wide range of industries – from toolmaking to biomedical applications.